Capability Study Template

Capability Study Template - Input your target and tolerances for the x and y coordinates. For example, a quality analyst uses a normal capability analysis to evaluate how well the process meets the specifications of 20 ± 0.1 mm, based on a normal distribution of the data. Web process capability is defined as a statistical measure of the inherent process variability of a given characteristic. Web process capability study helps in product and process design, vendor sourcing, production planning, and manufacturing process control. It has space for up to 35 characteristics and 100 measurements. Category | supply chain & operations , data analysis. The template automatically creates all diagrams and calculates all quality parameters. The target for the offset (d4:e4) is usually zero: A goal of any organization should be ongoing process improvement. Assists designers in selecting or designing processes. A few ways a process capability study helps: Web select the template from qi macros menu. The template has several tabs, select the cp cpk true position worksheet: Web free lean six sigma templates. Input your target and tolerances for the x and y coordinates. There are seven cp cpk worksheets in the template. Why professionals choose simple sheets. Web process capability study helps in product and process design, vendor sourcing, production planning, and manufacturing process control. Web a process capability study uses data from a sample to predict the ability of a manufacturing process to produce parts conforming to specifications. The template automatically creates. Collect the data and put it into excel_template. Moving beyond such a description, this article focuses on the untapped power of capability analysis and shows you how to use. Web the steps for conducting a process capability study are: A process capability study measures the capability of a specific piece of equipment or a process under specific operating conditions. Web. Also input the allowable offset for x and y. This prediction enables us to qualify a new manufacturing process as being fit for use in production. Input target, tolerances and measurements. The output of this measurement is usually illustrated by a chronological control sample, a histogram and calculations that predict how many parts will be produced out of specification (oos).. Many articles describe the difference between p p and c p simply: Specifying requirements of new equipment. It has space for up to 35 characteristics and 100 measurements. The target for the offset (d4:e4) is usually zero: A goal of any organization should be ongoing process improvement. Web process capability is a measurable property of a process against the specification, expressed as a process capability index (e.g., cpk or cpm ). 1.6k views 2 years ago operations. Web process capability study helps in product and process design, vendor sourcing, production planning, and manufacturing process control. Web what's inside the process capability template? Moving beyond such a description,. Capability studies help identify sources of variation, validate measurement systems, and drive process improvements. One is short term, one is long term. Web the process capability index is a statistical measure that quantifies a process’s ability to meet specifications. A goal of any organization should be ongoing process improvement. Web four steps for process capability study with excel template. Qi macros template calculates cp, cpk, pp, and ppk. Establishing an interval between sampling. Comparing the output to the spec. Web measurement data is required to calculate the process capability. This prediction enables us to qualify a new manufacturing process as being fit for use in production. It has space for up to 35 characteristics and 100 measurements. Web process capability study helps in product and process design, vendor sourcing, production planning, and manufacturing process control. Web free lean six sigma templates. What is process capability analysis? Category | supply chain & operations , data analysis. Taking action to improve the process. Web capability analysis is a critical tool for ensuring process performance meets specifications and requirements. Many articles describe the difference between p p and c p simply: Web use normal capability analysis to evaluate the potential (within) and overall capability of your process based on a normal distribution. Web the steps for conducting a. Qi macros template calculates cp, cpk, pp, and ppk. This prediction enables us to qualify a new manufacturing process as being fit for use in production. This step should be institutionalized. Web select the template from qi macros menu. Web the steps for conducting a process capability study are: The following is an excerpt from the quality engineering handbook by thomas pyzdek, © qa publishing, llc. Access vital capability for reports and track cpk/ppk. The data can be entered into an excel template for evaluation. The output of this measurement is usually illustrated by a chronological control sample, a histogram and calculations that predict how many parts will be produced out of specification (oos). A process capability study measures the capability of a specific piece of equipment or a process under specific operating conditions. Also input the allowable offset for x and y. Web the process capability indices p p and c p describe how closely a process can operate within its specification limits. Process capability analysis is a key method used in lean six sigma and quality control and management. Web a good practice to capture the reliability of our pp estimate is to use minitab’s confidence intervals, available in stat>quality tools>capability analysis>options. Web use normal capability analysis to evaluate the potential (within) and overall capability of your process based on a normal distribution. What is process capability analysis?

Capability Study Excel Template SampleTemplatess SampleTemplatess

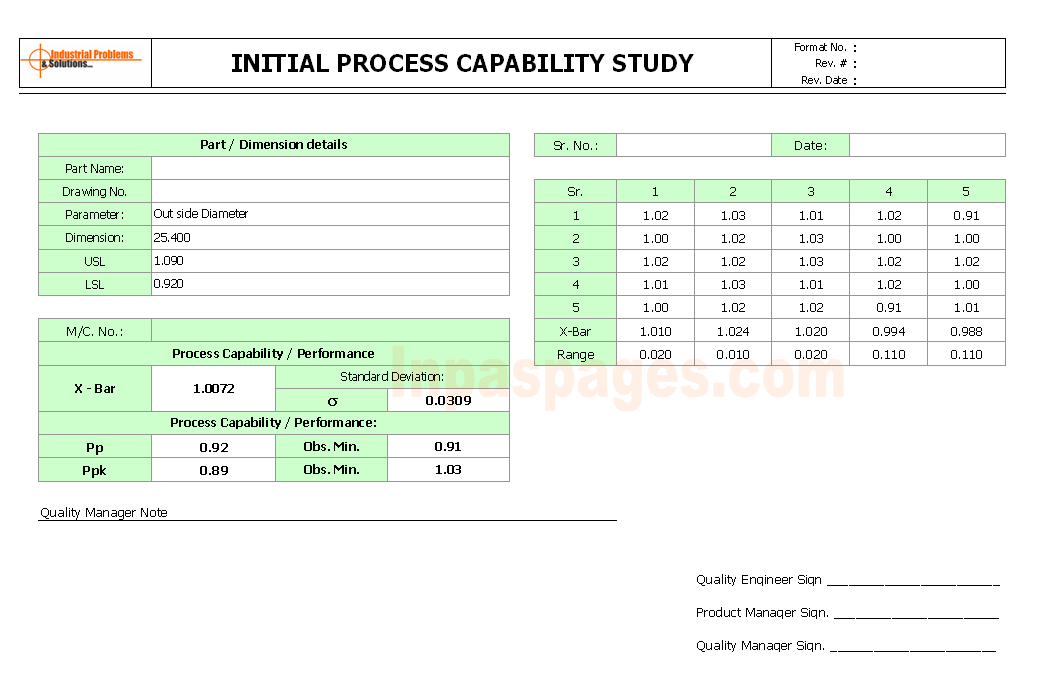

Initial process capability study cp cpk ppk analysis

Cpk Excel Template

How To Do A Capability Study In Excel Study Poster

Industrial Knowledge on Tumblr

8 Capability Study Excel Template Excel Templates

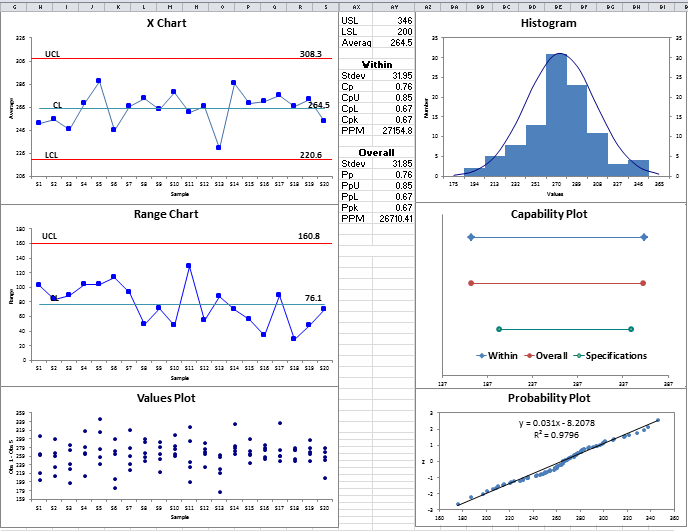

Capability Suite Excel Just Like Minitab Capability Sixpack™

Machine Capability Study Excel Template Master of Documents

Capability Assessment 04 PowerPoint Template

Capability PDF

The Output Of This Measurement Is Usually Illustrated By A Chronological Control Sample, A Histogram And Calculations That Predict How Many Parts Will Be Produced Out Of Specification (Oos).

Web Free Lean Six Sigma Templates.

Example Of The Qi Macros Cp Cpk Template.

Input Target, Tolerances And Measurements.

Related Post: