Lapping Drawing

Lapping Drawing - By using lapping process we can obtain high accuracy in dimensions. (3) lapping is performed at low speed and low pressure, generating minimal heat. 30k views 3 years ago mapeh (music, arts, pe, health) show how to make overlapping artwork and. There are 2 types of lapping processes, diamond or conventional. Domed lapping produces a slender, uniform shape for lenses and other curved surfaces. Web lapping is a machining process in which two surfaces are rubbed together with an abrasive between them, by hand movement or using a machine. Web honing is a method of internal grinding used to achieve a precise surface finish and shape on the inside diameter (id) of a tube, bore, or hole. 8.7k views 3 years ago drawing from shapes. The lapping process is a fine finishing process, which leads to a surface with low roughness and high precision. Lapping is a precision operation and is and based on the cutting power of either a free abrasive grain in a carrier or a fixed abrasive particle within a composite lapping plate matrix. Lapping is an abrasive machining process in which abrasive grains dispersed either in a paste or a fluid are applied to the moving surface of an opposing formed tool (the lap) so that the individual grains follow a disordered path (din 8589). Web in this article we are going to learn about lapping, lapping is a simple process used to. Domed lapping produces a slender, uniform shape for lenses and other curved surfaces. This diagram can also be derived from a stitch chart by not drawing in the stitch legs but only the head and feet of the stitches. Lapping often follows other subtractive processes with more aggressive material removal as a first step, such as milling and/or grinding. Lapping. Web lapping is a machining process in which two surfaces are rubbed together with an abrasive between them, by hand movement or using a machine. 8.7k views 3 years ago drawing from shapes. Lapping can take two forms. 30k views 3 years ago mapeh (music, arts, pe, health) show how to make overlapping artwork and. Web teacher anne alfaro. 2.3k views 10 years ago. Web the principle of lapping is simple and based on the cutting power of either a free abrasive grain in a carrier or a fixed abrasive particle within a composite lapping plate matrix. This diagram can also be derived from a stitch chart by not drawing in the stitch legs but only the head and. Web the principle of lapping is simple and based on the cutting power of either a free abrasive grain in a carrier or a fixed abrasive particle within a composite lapping plate matrix. This diagram can also be derived from a stitch chart by not drawing in the stitch legs but only the head and feet of the stitches. 30k. 2.3k views 10 years ago. 6k views 4 years ago. This short presentation demonstrates how to draw lapping movement drawings for warp knitting pattern with the starter edition of the texmind warp. The drawing shows exactly the principle corresponding to the lapping process. This diagram can also be derived from a stitch chart by not drawing in the stitch legs. The lapping process is a fine finishing process, which leads to a surface with low roughness and high precision. The honing and lapping processes are both highly controlled. Conditioning rings and functional principle. Flat lapping can correct surface irregularities caused by sawing or grinding. Lapping is a precision operation and is and based on the cutting power of either a. Web the principle of lapping is simple and based on the cutting power of either a free abrasive grain in a carrier or a fixed abrasive particle within a composite lapping plate matrix. This process involves the use of a specialized machine that applies a fine abrasive slurry to the surface of the material being worked on. There are 2. Lapping has the following characteristics: Web lapping is a widely used process for achieving high levels of surface quality and precision in industrial manufacturing. Conditioning rings and functional principle. 6k views 4 years ago. This process involves the use of a specialized machine that applies a fine abrasive slurry to the surface of the material being worked on. The term lapping is used to describe a number of various surface finishing operations where loose abrasive powders are used as the grinding agent at normally low speeds. This method is highly useful to get perfect contact between two mating parts. This short presentation demonstrates how to draw lapping movement drawings for warp knitting pattern with the starter edition of. This diagram can also be derived from a stitch chart by not drawing in the stitch legs but only the head and feet of the stitches. (2) it can result in a very precise fit between mating surfaces. Lapping is an abrasive machining process in which abrasive grains dispersed either in a paste or a fluid are applied to the moving surface of an opposing formed tool (the lap) so that the individual grains follow a disordered path (din 8589). The use of rotational friction, speed, load and the addition of sand grains and fluid result in lapping or drilling. Lapping often follows other subtractive processes with more aggressive material removal as a first step, such as milling and/or grinding. Flat lapping can correct surface irregularities caused by sawing or grinding. The honing and lapping processes are both highly controlled. This method is highly useful to get perfect contact between two mating parts. The term lapping is used to describe a number of various surface finishing operations where loose abrasive powders are used as the grinding agent at normally low speeds. Web in this article we are going to learn about lapping, lapping is a simple process used to improve the surface finish, by using this method we can remove the minor imperfections on the surface. Domed lapping produces a slender, uniform shape for lenses and other curved surfaces. This is the symbolic image of the technological process of lapping. While the rotating lapping plate is moving, stock removal of material happens by the countless loose particles between the carrier surface (lapping plate) and the. Web unlike other cutting methods such as cnc, turning, milling, and grinding, lapping is a gentle stock removal process that uniformly transfers the flatness of the lapping plate to the component being lapped, minimizing the introduction of any additional stress. Web lapping is an abrading process used to produce geometrically true surfaces, improve dimensional stability, or provide a very close fit between two contact surfaces. Lapping can take two forms.

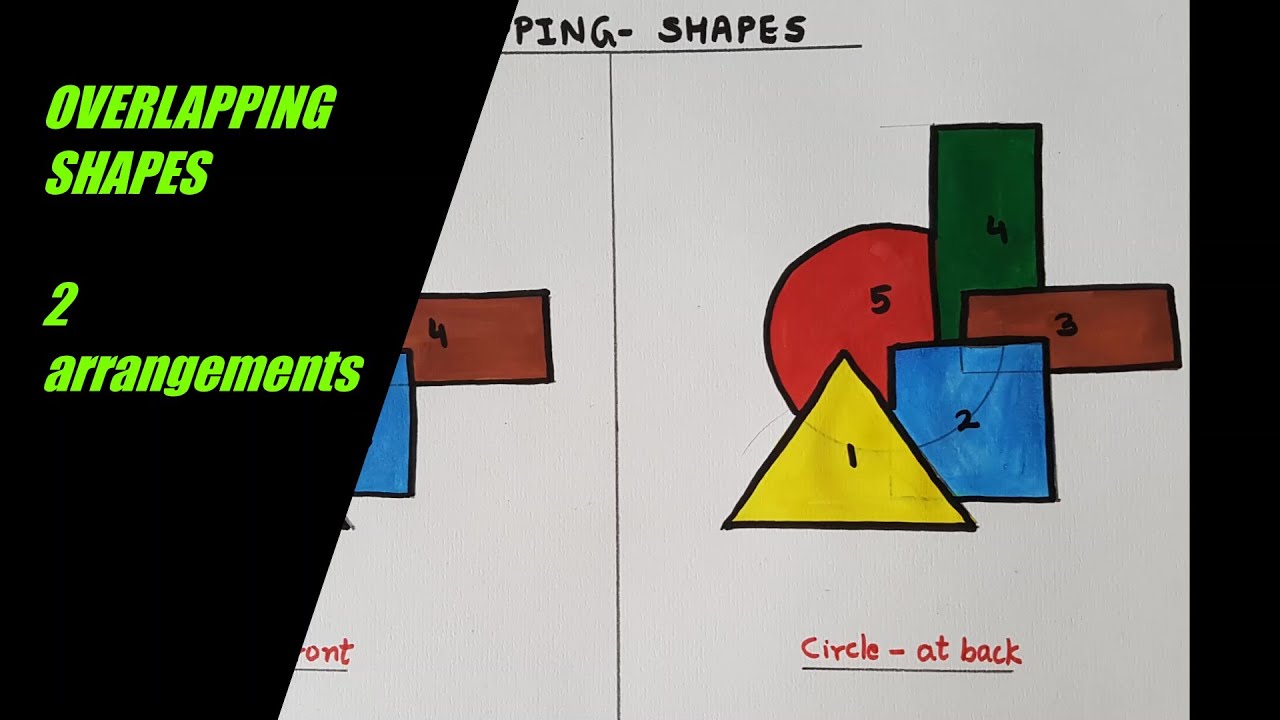

Overlapping Shape Drawing YouTube

Drawing Overlapping Objects Art Starts

24 Best images about Overlapping Drawing on Pinterest Happenings

How to draw OVERLAPPING SHAPES / 3D SHAPES / Simple and easy / step

Sitting On Someone'S Lap Drawing Reference Drawing People Sitting

How to Draw Overlapping Lines Fruits YouTube

Ovver lapping Drawing, geometrical design,how to draw geometrical

Lapping Process Surface Finishing Process Abrasive Machining PPT

Centerless Cylindrical Lapping

Overlapping Drawing Project Art Projects for Kids Overlapping art

The Machining Process Of Lapping Involves Two Surfaces That Are Rubbing Together With A Lapping Medium (Lapping Fluid And Lapping Grit) Trapped Between Them.

It Describes The Methods Of Lapping Outer Cylindrical Surfaces, Namely, Ring Lapping, Machine.

Web Lapping Is A Widely Used Process For Achieving High Levels Of Surface Quality And Precision In Industrial Manufacturing.

Lapping Has The Following Characteristics:

Related Post: