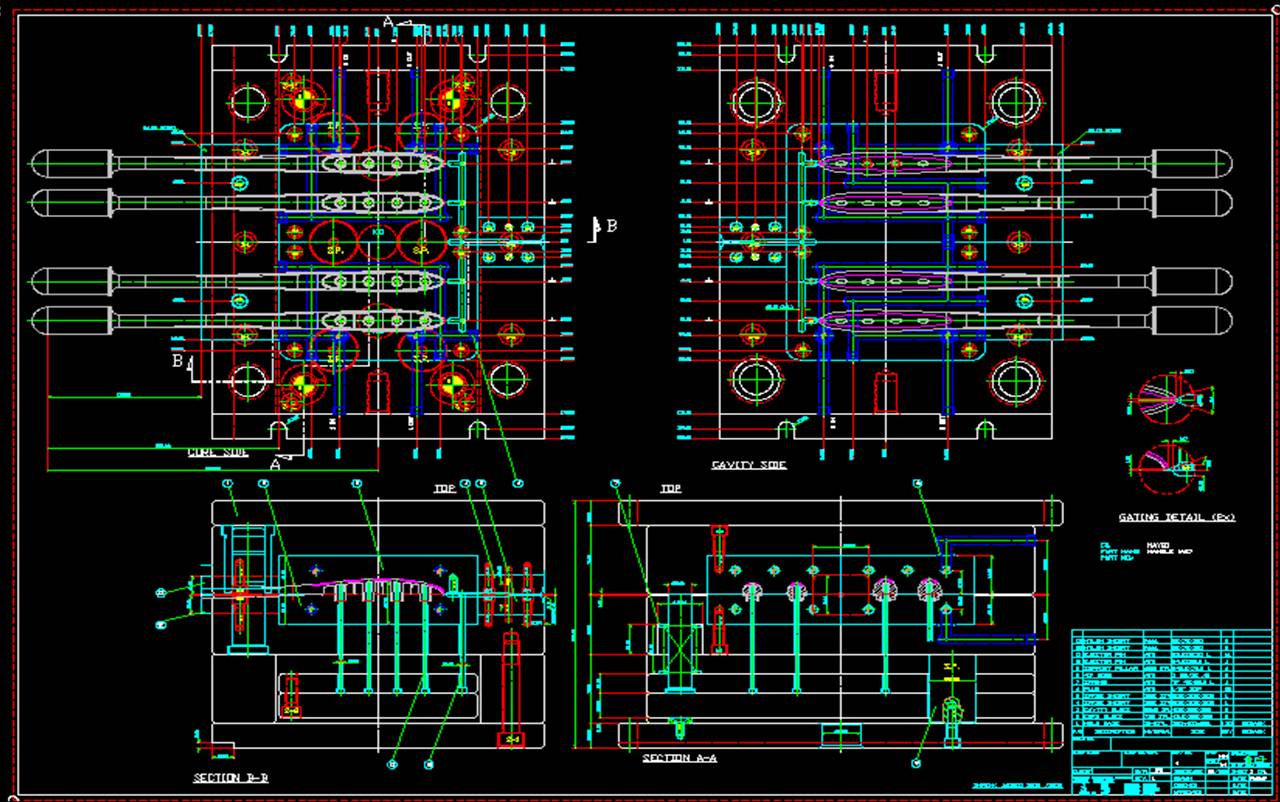

Mold Draw

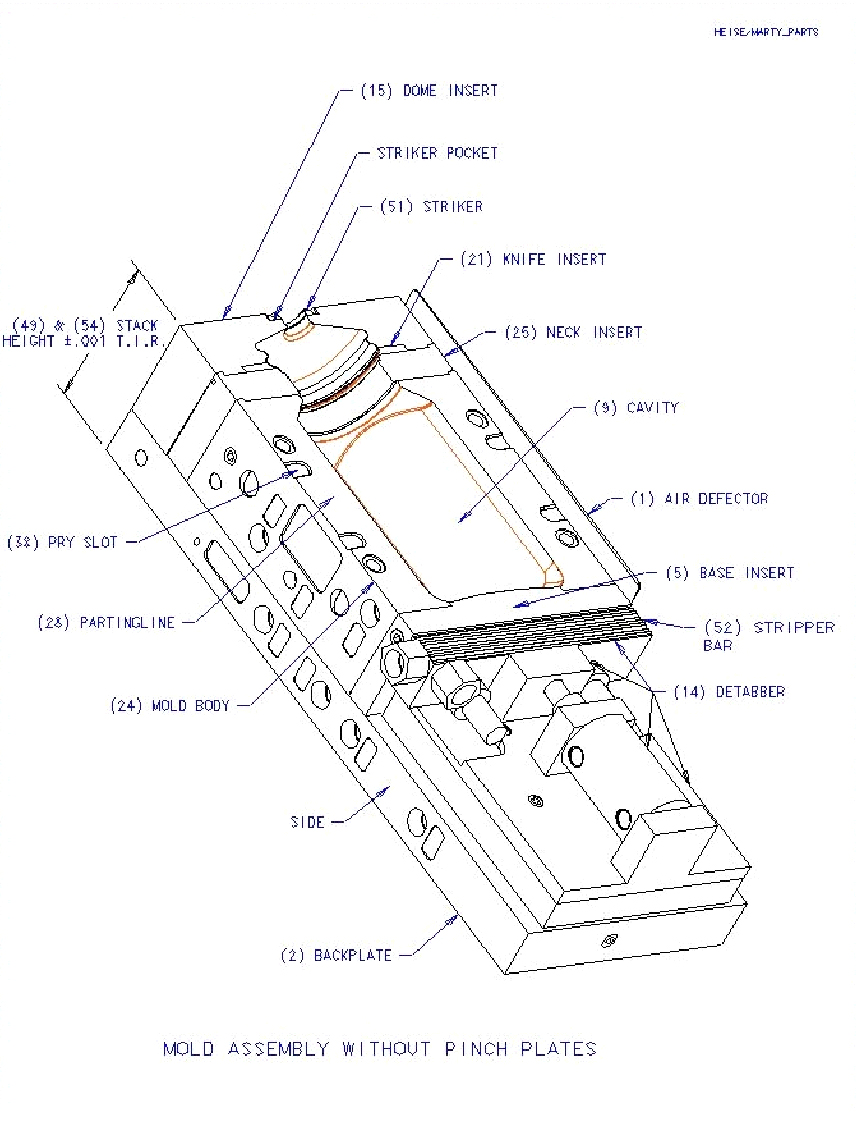

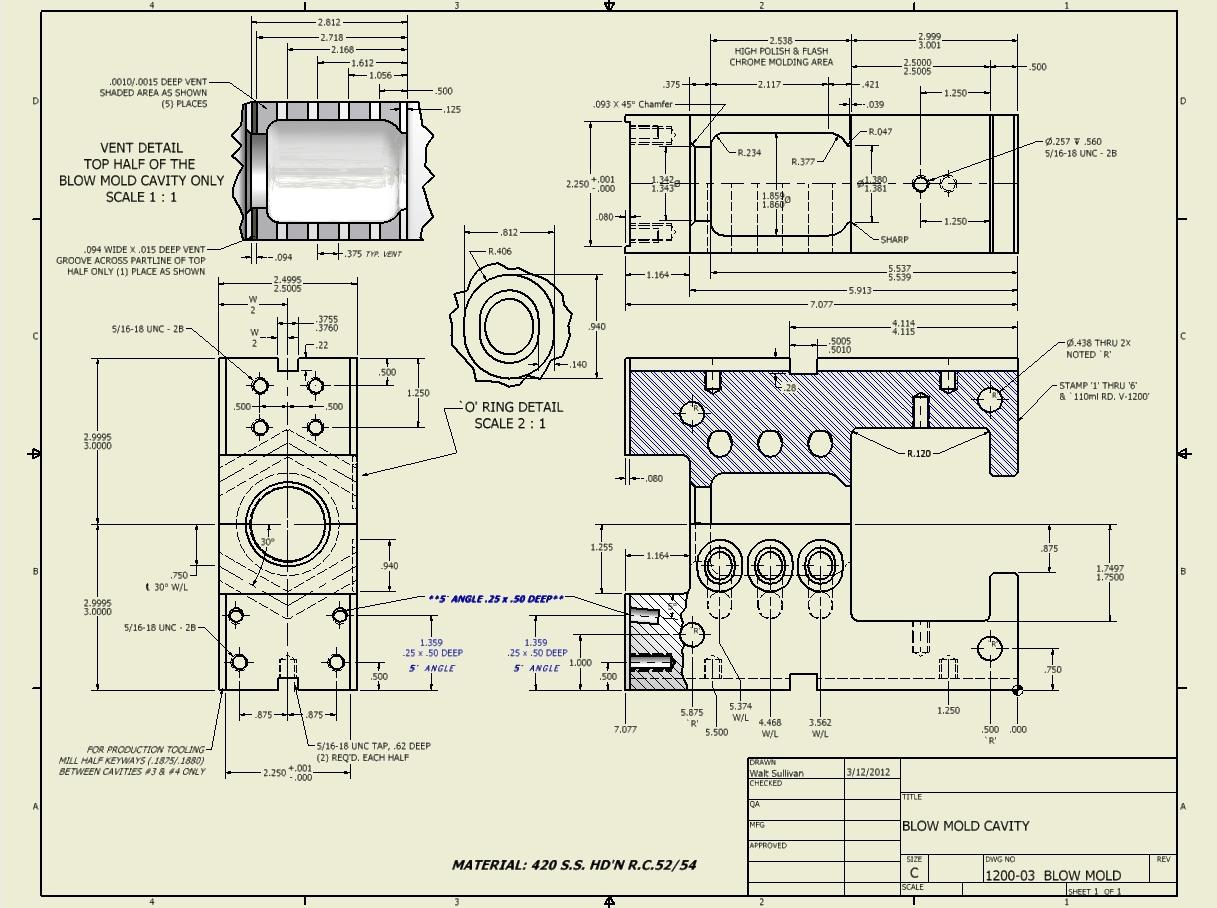

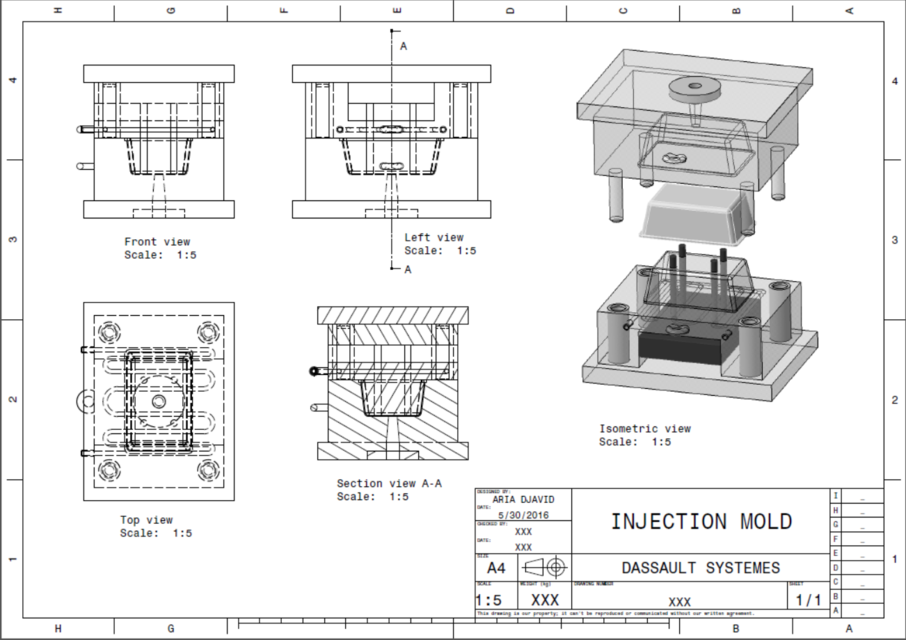

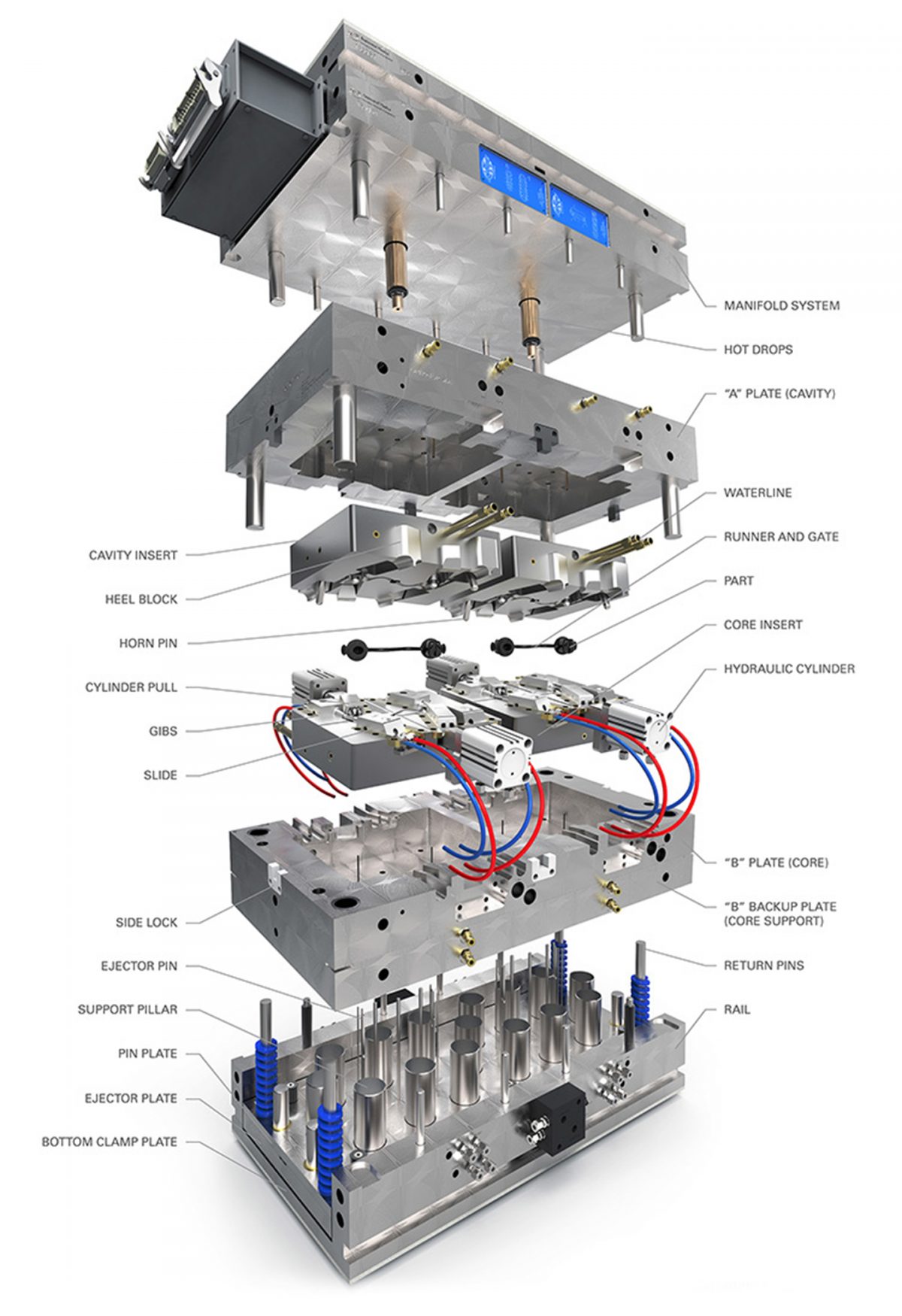

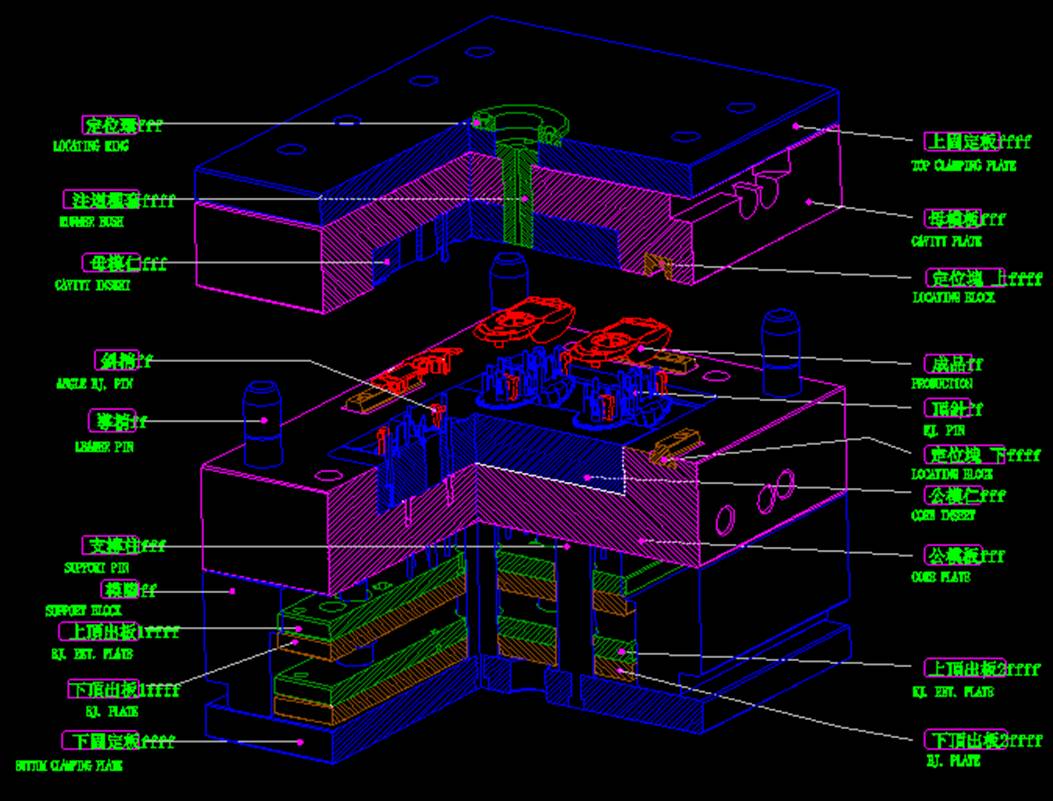

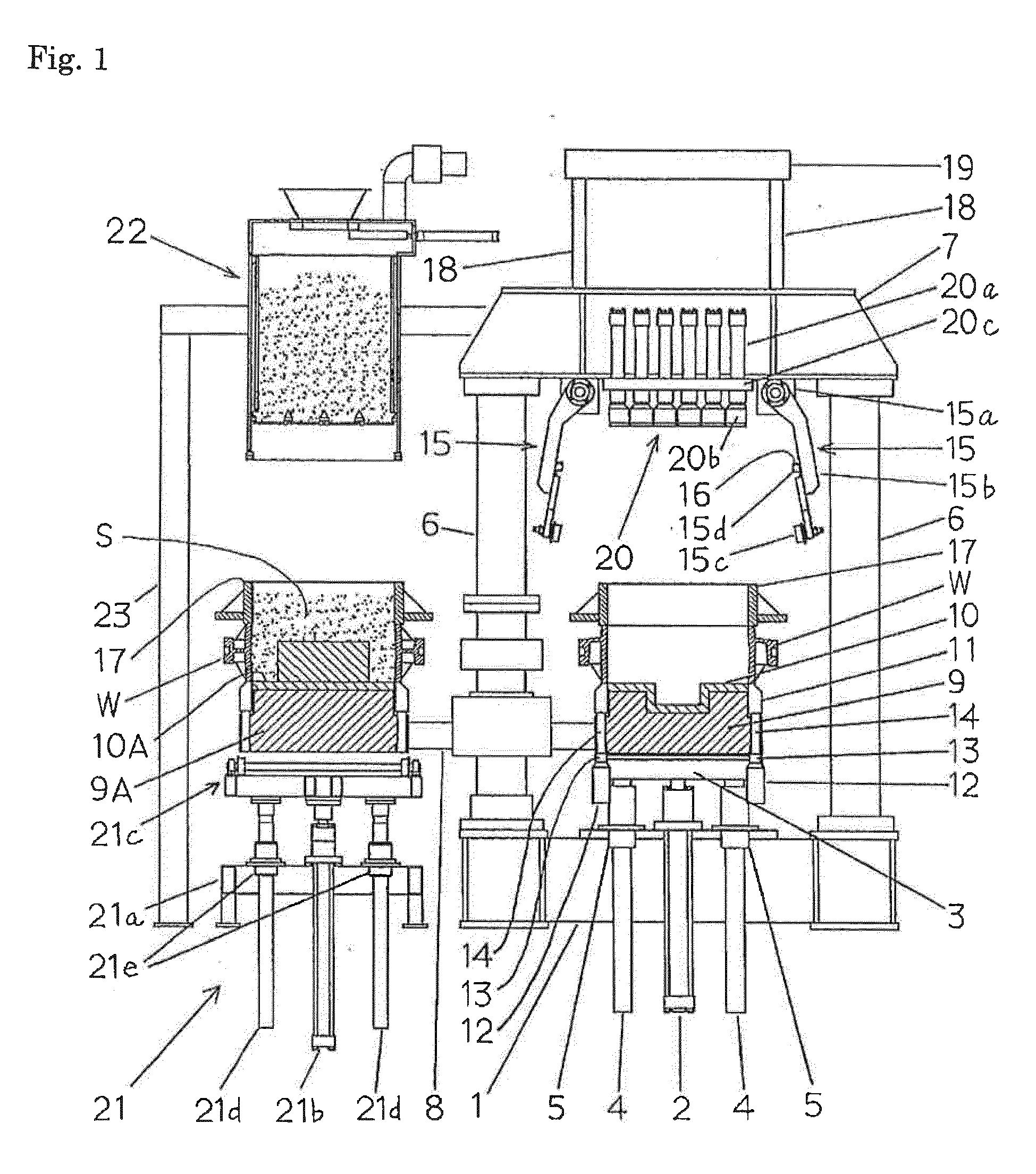

Mold Draw - Gate refers to where the plastic enters into the cavity of the mold. Generally, mold polishing techniques use wool wheels, whetstone strips, and sandpaper for manual polishing. Injection molding sliders and lifters are mechanisms that release a molded plastic part when an injection mold opens. Xcentric offers a range of additive manufacturing technologies to support projects of all types. The entire collection is set to see an early release. Texas injection molding uses spi mold polish standards to specify mold finishes multiple applications and surface finishes. Draw ratio is a calculation that your thermoformer uses to determine the minimum thickness of the plastic sheet to produce your part. Fundamentally, thermoforming works by drawing a hot sheet of thermoplastic down onto a mold. 40 views 2 months ago. Web outbound vanderbilt senior tyrin lawrence, no. You should be looking at how to make a simple but effective mold—a mold that generates the part the way you want it but avoids adding cam actions and lifters if they are not necessary. Draft is a taper applied to the faces of the part that prevent them from being parallel to the motion of the mold opening. Detect. The draft angle of ribs is generally controlled at 0.5~2°, and 1~1.5° are most common. Draft is a taper applied to the faces of the part that prevent them from being parallel to the motion of the mold opening. Detect possible allergic responses to various substances in the environment (see test includes) and evaluate for hay fever, asthma, atopic eczema,. You should be looking at how to make a simple but effective mold—a mold that generates the part the way you want it but avoids adding cam actions and lifters if they are not necessary. We made this as an example of how you can use machine learning in fun ways. Of course, it doesn’t always work. 6 among uncommitted. First, ensure you have a solid object, rather than abutting surfaces. Gate refers to where the plastic enters into the cavity of the mold. It does this by removing the convex parts of the mold through plastic deformation and cutting. Web outbound vanderbilt senior tyrin lawrence, no. Draft is a taper applied to the faces of the part that prevent. Web what is thermoforming draw ratio? The size of the draft angle. Draft is a taper applied to the faces of the part that prevent them from being parallel to the motion of the mold opening. First, ensure you have a solid object, rather than abutting surfaces. The injection molding draft angle is a critical parameter in this process that. The two types of gates are as follows: Web in order for the part to be ejected smoothly in the injection molding process, the draft angle is necessary. Web what is draft in injection molding? Draw ratio is a calculation that your thermoformer uses to determine the minimum thickness of the plastic sheet to produce your part. These sheets can. This means that certain design elements such as a “t” shaped rib section cannot be “molded. Web what is draft in injection molding? The entire collection is set to see an early release. Web we start off deciding which direction the mold will open relative to the molded part. Injection molding sliders and lifters are mechanisms that release a molded. It is important to remember that the start of the thermoforming process is always a flat sheet of material. Web what is draft in injection molding? Slides, or sliders, release external undercuts, recesses or projections on a part’s outer surface that prevent the part’s direct removal from the mold cavity. Fundamentally, thermoforming works by drawing a hot sheet of thermoplastic. 6 among uncommitted shooting guards in the transfer portal, might fit the mold of what the duke basketball staff is looking for in a backup perimeter. First, ensure you have a solid object, rather than abutting surfaces. Web in order for the part to be ejected smoothly in the injection molding process, the draft angle is necessary. Generally all plastic. Generally, mold polishing techniques use wool wheels, whetstone strips, and sandpaper for manual polishing. Texas injection molding uses spi mold polish standards to specify mold finishes multiple applications and surface finishes. Xcentric offers a range of additive manufacturing technologies to support projects of all types. In this article, our discussion will focus on draft angle injection molding. Web what is. The two types of gates are as follows: First, ensure you have a solid object, rather than abutting surfaces. So far we have trained it on a few hundred concepts, and we hope to add more over time. This overview lists typical mold design tasks and the solidworks functions that provide solutions to help you complete those tasks. Fundamentally, thermoforming works by drawing a hot sheet of thermoplastic down onto a mold. It divides the surface area of the mold by the footprint, or top surface, of the heated sheet. The entire collection is set to see an early release. Web what is mold polishing? Mold design is one of the most complex aspects of product design. Whether you're a beginner or an experienced artist, our guide will help you master the art. Web each watch is priced at $1,500 usd, with a special edition collector’s box set, limited to 75 examples, available via a draw for $18,000 usd. Draw ratio is a calculation that your thermoformer uses to determine the minimum thickness of the plastic sheet to produce your part. Web in figure 1 below, you can see how the mold is in two halves, the line of draw, and how the two halves would come together at the parting line. From rapid prototyping to product creation at scale, xcentric, together with quickparts, brings speed and scale to your prototype, parts, and production projects. It does this by removing the convex parts of the mold through plastic deformation and cutting. Slides, or sliders, release external undercuts, recesses or projections on a part’s outer surface that prevent the part’s direct removal from the mold cavity.

Mold Drawing at GetDrawings Free download

Mold Drawing at GetDrawings Free download

Mold Drawing at Explore collection of Mold Drawing

Mold Drawing at Explore collection of Mold Drawing

Anatomy of a Mold PTI Plastic Injection Molding

Mold Drawing at GetDrawings Free download

Mold Drawing at GetDrawings Free download

Mold Drawing at GetDrawings Free download

Mold Drawing at GetDrawings Free download

Mold Drawing at GetDrawings Free download

Web This Overview Lists Typical Mold Design Tasks And The Solidworks Functions That Provide Solutions To Help You Complete Those Tasks.

Injection Molding Sliders And Lifters Are Mechanisms That Release A Molded Plastic Part When An Injection Mold Opens.

Plastic Injection Mold Polishing Is A Technique That Helps To Obtain Smooth Mold Surfaces.

We Are Going To Look At The Things That One Has To Consider When Mold Drawing And Designing Or Injection Molding Process And How Each Of These Considerations Affects The Final End Product.

Related Post: