Scarf Joint Template

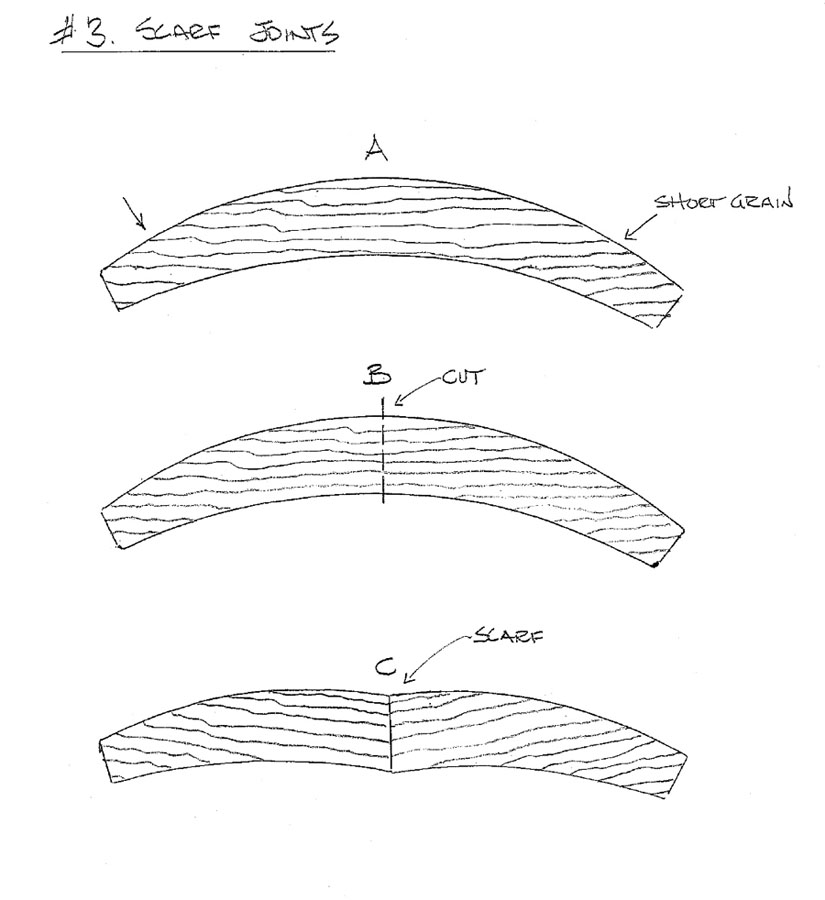

Scarf Joint Template - Web how to create a scarf joint like a pro! Web learn how to make a scarf joint; The scarf joint is an overlapping joint that can be used to connect together two shorter pieces of lumber to make a longer one. Web in benson's book building the timber frame house he has some great instructions to make a plywood template for this joint. Timber frame joints / leave a comment. On the end of two plates, a mirror imaged, angled half lap joint is cut. Plank so the end to be joined is flush with the end of the jig. Details include using this special joint for making repairs to furniture or trim. Web make this simple jig. Learn more about the technique here. It is commonly used in various projects, such as furniture making, flooring installation, and even musical instrument construction. I'm planning on creating a template similar to how he suggests it (i may make my splay longer than he recommends if my timber lengths allow for it). Web in benson's book building the timber frame house he has some great instructions. 2.8m views 4 years ago #carpentry #woodwork #robinclevett. The scarf joint is an overlapping joint that can be used to connect together two shorter pieces of lumber to make a longer one. Scarf joints come in many shapes, but the main purpose is the same: I'm planning on creating a template similar to how he suggests it (i may make. Snap a centerline along the template. Web a scarf joint is an ancient technique used in woodworking to join two pieces of timber together at an angle. Details include using this special joint for making repairs to furniture or trim. Web measuring template and scarf joint jig created. Here’s how to make a scarf joint woodworking: The scarf joint has since become a cornerstone of woodworking, providing strength, stability and versatility to the craft. Typically about 3′ long and cut at approximately 66 degrees, the scarfs have mortice and tenon joints on each end. Even if you’re only making one of these chairs, it’s a good idea to use a template to mark the two arms,. Start by selecting the wood for your scarf joint. Here’s how to make a scarf joint woodworking: There are many variations of scarf joints to be found and each of them has a function that they excel at over other scarfs for whatever application you are using them for. Web the challenge when using a router to cut scarf joints. Snap a centerline on the beam. Web measuring template and scarf joint jig created. The scarf joint has since become a cornerstone of woodworking, providing strength, stability and versatility to the craft. Scarf joints come in many shapes, but the main purpose is the same: Plank so the end to be joined is flush with the end of the jig. Web how to create a scarf joint like a pro! 4.5m views 8 years ago timber framing. This type of joint has been used since antiquity and was popularized early on by shipbuilders. Web the solution is the scarf joint. When trying to determine which joint is best for your situation you need to understand the loads and forces that. Don't concentrate sanding pressure right at the joint line—feather out the sanding several inches to each side of the seam line. Start by selecting the wood for your scarf joint. Typically about 3′ long and cut at approximately 66 degrees, the scarfs have mortice and tenon joints on each end. There are many variations of scarf joints to be found. 2.8m views 4 years ago #carpentry #woodwork #robinclevett. This type of joint has been used since antiquity and was popularized early on by shipbuilders. Web scarf joint with a wedge. Don't concentrate sanding pressure right at the joint line—feather out the sanding several inches to each side of the seam line. Nothing beats the look and strength of an undersquinted. Timber framing scarf joint cut in 8 x 8 oak, basic timber framing techniques for use in post and beam construction. There are many various ways to cut scarf joints. Web a scarf joint connects two timbers together to make one. Web a scarf joint is an ancient technique used in woodworking to join two pieces of timber together at. Typically about 3′ long and cut at approximately 66 degrees, the scarfs have mortice and tenon joints on each end. Snap a centerline along the template. Index the line on the beam to the center lines on the template. In this detail, we illustrate three types of methods to connect the two beams and joints together. Web in benson's book building the timber frame house he has some great instructions to make a plywood template for this joint. Two ash or oak pegs securely hold the two planes together. On the end of two plates, a mirror imaged, angled half lap joint is cut. Slope of 8 to 1, which gives an overlap of 6 in. There are many various ways to cut scarf joints. Don't concentrate sanding pressure right at the joint line—feather out the sanding several inches to each side of the seam line. This type of joint has been used since antiquity and was popularized early on by shipbuilders. Details include using this special joint for making repairs to furniture or trim. Learn more about the technique here. The method known as “scarfing” is used for the joining of timber in the direction of its length, enabling the workman to produce a joint with a smooth or flush appearance on all its faces. There are many variations of scarf joints to be found and each of them has a function that they excel at over other scarfs for whatever application you are using them for. The one shown above has become vtws favorite over time because the integrity of the joint holds up well after the timber shrinks, unlike some other.

Timber Framing Scarf Joint YouTube

Scarf Joint CAD/PDF Plans — KatzMoses Woodworking

EP12 How To Create An Easy Scarf Joint That Works DIY Boatbuild

Scarf Joint With A Wedge Timber Frame HQ

Scarf Joint CAD/PDF Plans — KatzMoses Woodworking

Scarf Joint Template 3″ and 31/8″ — Bob's Wood Stuff

Tablesaw Jig for Making Scarf Joints FineWoodworking

![36 Woodworking Joints EASY To Make [2019 update]](https://baubeaver.de/wp-content/uploads/woodworking-joints-Oblique-hooked-scarf-joint.png)

36 Woodworking Joints EASY To Make [2019 update]

Making Scarf Joints Woodworking Blog Videos Plans How To

Scarf Joint for Wood Elegance and Strength Don Tai (Canada) Blog

All Drawings Are Printable And Delivered Instantly Through A Download Link.

Web How To Create A Scarf Joint Like A Pro!

Snap A Centerline On The Beam.

Plank So The End To Be Joined Is Flush With The End Of The Jig.

Related Post: