Temperature Mapping Protocol Template

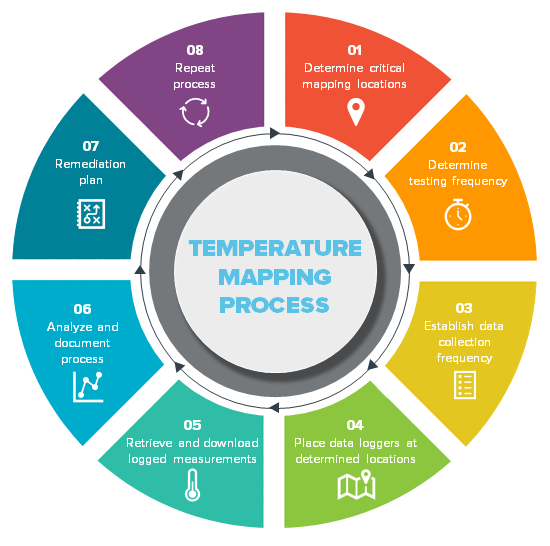

Temperature Mapping Protocol Template - This happens mainly in vehicles which has one cooling unit and having fan only at one end. This mapping study is carried out as per who technical report series, no. To describe a procedure for temperature mapping. Carry out the mapping study. Web thereafter the higher & lower cut off will be 7 & 3°c respectively. Get your free temperature mapping report template now. Web this protocol will define the methods and documentation used to qualify cold chamber for temperature mapping. Download from below given link. The goal is to validate that the unit can maintain temperatures within the required range during various stress tests such as oq/pq stability tests, door opening tests, and power failure tests. Web place 31 numbers of temperature/humidity data logger/sensor in room as per attached drawing and table no. A temperature mapping exercise is required for any space allocated for the storage and handling of products with a specified labelled storage temperature. (this feature is based on the manufacturer and models of the cooling unit) c. Hod of engineering and qa. As per 5 meter criteria only 31 data logger is required hence 31 data logger is considered for. New equipment installed in approved rm area. One data logger will be placed outside the cold room for recording external temperature. If this is the first time the logtag® analyzer has been used, the “configuration profile” window may be empty as shown in fig. Hod of engineering and qa. Data logger/sensor shall be placed within 5 meter of the area. Temperature on one end of the vehicle goes beyond limits. Carry out the mapping study. Web thereafter the higher & lower cut off will be 7 & 3°c respectively. Proper temperature & humidity recovery following a door opening under 70% loaded conditions. Web this protocol will define the methods and documentation used to qualify cold chamber for temperature mapping. Web center the temperature trend on the desired temperature, 80°c for example, before starting the test. Proper temperature & humidity recovery following a door opening under 70% loaded conditions. To lay down the procedure for temperature mapping. As per 5 meter criteria only 31 data logger is required hence 31 data logger is considered for temperature mapping. Signing of this. Develop a cohesive and actionable mapping report for pharma, biotech, and logistics with this detailed temperature mapping report template including practical examples. (this feature is based on the manufacturer and models of the cooling unit) c. Data logger/sensor shall be placed within 5 meter of the area in the respective room. Review relevant guidelines and regulations. As per 5 meter. As per 5 meter criteria only 31 data logger is required hence 31 data logger is considered for temperature mapping. Signing of this approval page of temperature & relative humidity mapping protocol indicates agreement with the temperature & relative humidity mapping approach described in this document. To describe a procedure for temperature mapping. Global expertise with local reach. A temperature. Web template for temperature mapping protocols & reports : A temperature mapping exercise is required for any space allocated for the storage and handling of products with a specified labelled storage temperature. To establish that the temperature and/or relative humidity conditions across the room or area are within the prescribed limits during extreme external weather conditions. To lay down the. Web 1.0 objective : This document discusses guidelines for temperature mapping studies and qualification of cold storage facilities, vehicles, and packaging used in the pharmaceutical industry. Develop a cohesive and actionable mapping report for pharma, biotech, and logistics with this detailed temperature mapping report template including practical examples. The goal is to validate that the unit can maintain temperatures within. New equipment installed in approved rm area. This will not afect peak variance in most cases. Web proper temperature & humidity control and distribution under 70% loaded conditions. Web the temperature & humidity distribution verification protocol is a comprehensive document, which will be used to guide the executants, in the verification of the temperature & humidity distribution inside the Web. Implement the recommendations identified in the mapping report. Web 1.0 objective : This document discusses guidelines for temperature mapping studies and qualification of cold storage facilities, vehicles, and packaging used in the pharmaceutical industry. Web thereafter the higher & lower cut off will be 7 & 3°c respectively. Data logger/sensor shall be placed within 5 meter of the area in. If this is the first time the logtag® analyzer has been used, the “configuration profile” window may be empty as shown in fig. The goal is to validate that the unit can maintain temperatures within the required range during various stress tests such as oq/pq stability tests, door opening tests, and power failure tests. To establish that the temperature and/or relative humidity conditions across the room or area are within the prescribed limits during extreme external weather conditions. Global expertise with local reach. Proper temperature & humidity recovery following a door opening under 70% loaded conditions. Data logger/sensor shall be placed within 5 meter of the area in the respective room. Analyze and interpret the temperature mapping data. The temperature mapping procedures should: Signing of this approval page of temperature & relative humidity mapping protocol indicates agreement with the temperature & relative humidity mapping approach described in this document. New equipment installed in approved rm area. Get your free temperature mapping report template now. Web center the temperature trend on the desired temperature, 80°c for example, before starting the test. Web template for temperature mapping protocols & reports : Set the ofset to move the trend higher or lower using the freezer controller. Download from below given link. Temperature mapping establishes the temperature distribution within the zone being mapped and it locates hot and cold spots.

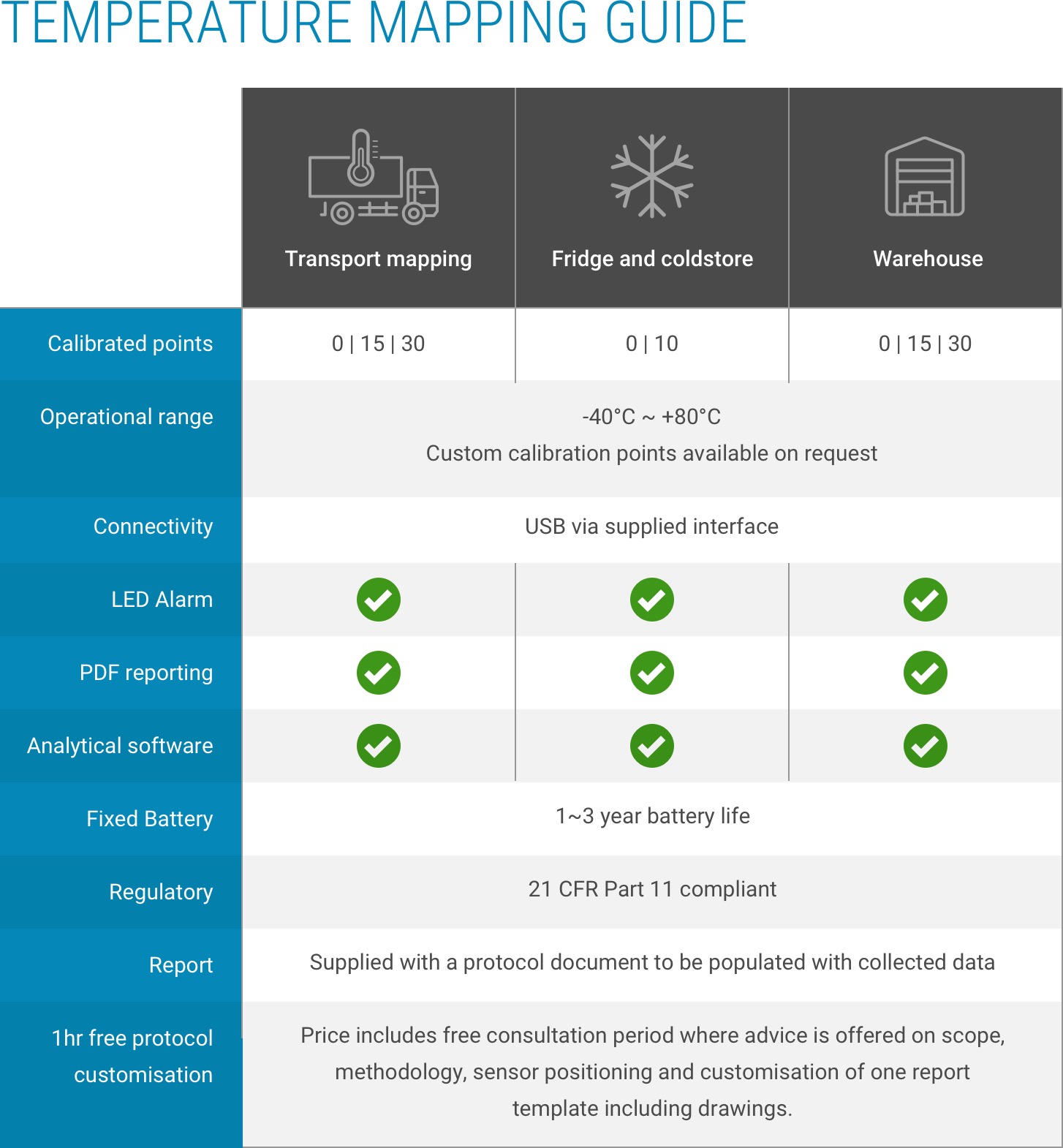

The Guide to Temperature Mapping

Temperature Data Loggers Downloading in 5 Steps.

Temperature Mapping Protocol Template

Temperature Mapping Protocol Template

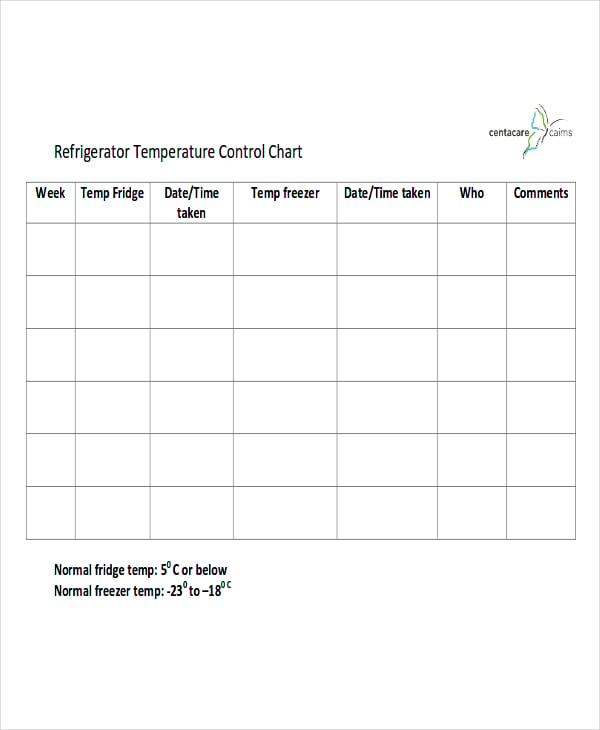

Temperature Mapping Qualification Protocol For Refrigerator

The complete industrial guide to temperature mapping

Temperature Mapping Protocol Template

Temperature Mapping Protocol Template

The complete industrial guide to temperature mapping

Temperature Mapping Protocol Template

This Will Not Afect Peak Variance In Most Cases.

Develop A Cohesive And Actionable Mapping Report For Pharma, Biotech, And Logistics With This Detailed Temperature Mapping Report Template Including Practical Examples.

Web Open The Window By Clicking On The <Logtag®> Option, As Shown In Fig.

Hod Of Engineering And Qa.

Related Post: